OUR STAINLESS STEEL PANEL MANUFACTURING STEPS

Because the primary component of this tank is metal, it naturally reacts with water and oxygen to form iron oxide (a.k.a rust). While they are typically durable, they will not be as sturdy as concrete or metal tanks, particularly in high-pressure functions. The zinc-alloy coating on the pressed steelworks is the primary defense in opposition to rust. However, plastic tanks can be prone to UV degradation if exposed to direct sunlight for extended durations. Aquamate massive steel water tanks, from 5,000 gallons to 102,000 gallons, are available via our approved sellers. The internal polythene lining works as an extra barrier to forestall corrosion and to keep away from metal leakage into water. As obvious, these tanks are made of chrome steel plates which provide high strength to the structure. Multiple panel sizes are available depending on the thickness of the coating required.

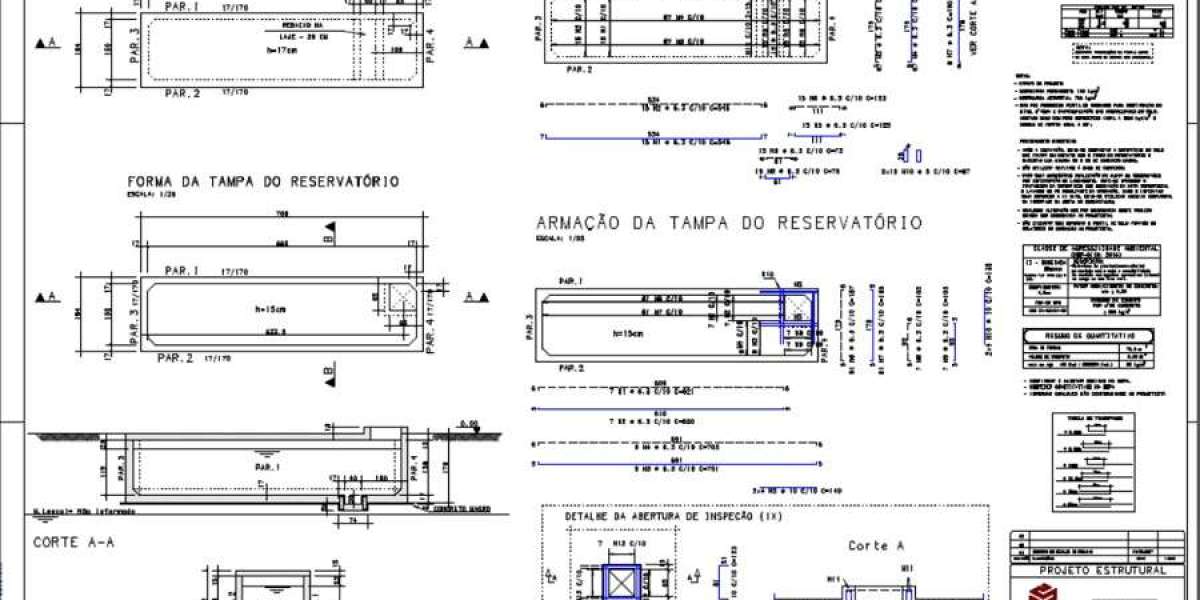

Our steel water tanks are available in 9 commonplace sizes, from 130″ to 512″ diameter, reservatório tipo taça coluna seca providing you with a spread of sizes and volumes to match your residence, business, ranch or reservatório tipo taça coluna Seca farm’s necessities. The stainless-steel materials has steady physical and chemical properties, does not impact the water quality, and ensures clear and hygienic ingesting water. Their lightweight nature permits for straightforward transportation and installation, even in distant areas. Plastic tanks can be found in quite a few sizes and shapes, offering flexibility for different purposes. All of our tanks are installed by Aquamate trained and licensed technicians, that means you probably can ensure that your metal water tank will stand the check of time.

A new technique Contaminants, subsequently, should not be allowed to settle in the reservoir; they want to be eliminated as quickly as possible by way of filters and water coalescers. As rotational velocity diminishes, contaminants settle at the bottom center of the reservoir, where they can be filtered out. Cylindrical reservoir with stationary oil, top, leaves contaminants equally distributed. Rotating the fluid, middle, directs contaminants to the middle of rotation. The handiest method to do this is to undertake a reservoir form totally different from the normal "bath tub" that has turn into so prevalent.

Technical Specifications

A bypass filtration circuit, sometimes known as a kidney loop, works particularly well with the cylindrical reservoir. MONITORING RELAYS — TYPES AND APPLICATIONS

Inside is a baffle, display, or each to decelerate the flow of fluid from its entry into the reservoir until it reaches the pump suction line inlet. No unwanted substances might be accrued anyplace within the system as a end result of particles and other contaminants are repeatedly removed. Fluid from the kidney loop flows again to the reservoir through a tangentially oriented tube, Figure four. Return oil flows tangentially into the reservoir close to the underside. This results in less complicated maintenance procedures, longer fluid life, and higher system reliability.

Fuel Tanks

In evaluating two reservoirs with equivalent volumes, a cubic reservoir with prime, bottom, and sides 2-m sq. The main system pump draws fluid from the upper portion of the reservoir, where fluid is cleanest. A kidney loop typically incorporates an oil cooler or heater as properly. has a quantity of sixteen m3 . On the other hand, plate thickness for the cylindrical reservoir would only need to be 0.25 mm or much less. A cylindrical reservoir with the identical height and volume would have a diameter of about 2.fifty five m. With the cubic reservoir, facet plates would have to be 14 mm thick to face up to the hydrostatic stress from a column of oil, and bulging could be approximately 15 mm. On normal galvanized tank designs, the coating of the tank shell doesn’t imply a reduction of the galvanized zinc coatings, the epoxy and polyester coatings are in addition to the galvanizing process. Furthermore, diametral deformation from hydrostatic strain would be only about 1 mm.

This is because the geometry of a cylinder distributes stress from the hydrostatic strain evenly across the circumference of the reservoir. Conventional reservoirs comprise many surfaces and corners where contaminants can gather. The building want solely be robust and stiff sufficient to permit transporting the empty tank, which serves as a base for its flanges and connections and carries the load of the fluid. Instead, contaminants should stay suspended in the fluid for straightforward removal by filters. In a cylindrical reservoir, the hydrostatic stress itself presents no practical impact on the thickness of the side plate. Balmoral cylindrical sectional tanks are available in aluminium, galvanised, stainless-steel, powder and epoxy coated choices and hold FM Approval for fastened fire combating sprinkler methods. This form has already been in use for many years in aviation purposes, where any disturbance in the operation of a hydraulic system may show catastrophic.