When your production needs don't fit a standard solution, where do you turn? This is a common question for engineers and product developers. Often, the answer lies in Mold Customization. But what does this process truly involve, and how do you find the right partner for it? Let's explore this from a user's perspective.

At its core, Mold Customization is the process of designing and building a mold tailored to produce a specific part. This isn't an off-the-shelf product; it's a collaborative project between you and a Mold Customization Manufacturer. The journey typically starts with your component design. A capable Mold Customization Manufacturer will review your drawings or samples to understand the material, geometry, and production volume. This initial consultation is vital—it's where potential challenges are identified and the blueprint for a suitable tool is formed. For instance, creating a complex housing for a medical device requires a different approach than a simple bracket for consumer goods. The right Mold Customization service adapts to these distinct requirements.

You might wonder about the practical benefits. Why go through a custom process? The main advantage is fit. A custom-made mold is engineered for your part alone, which can lead to fewer production errors, less material waste, and a more efficient manufacturing cycle. When you engage a Mold Customization Manufacturer, you're not just buying a tool; you're investing in a solution designed for your operational rhythm. They consider factors like cooling channel placement for faster cycle times or selecting a steel grade that matches your expected production lifespan. This thoughtful approach to Mold Customization helps secure consistent output.

The relationship with your supplier is another key aspect. A responsive Mold Customization Manufacturer acts as a technical partner. They can provide feedback on your design to enhance manufacturability, suggest adjustments for durability, and support you during the sampling phase. This collaboration is what transforms a good Mold Customization experience into a great one. It's about finding a provider who listens and applies their expertise to meet your project's unique demands, helping bring your product to life as envisioned.

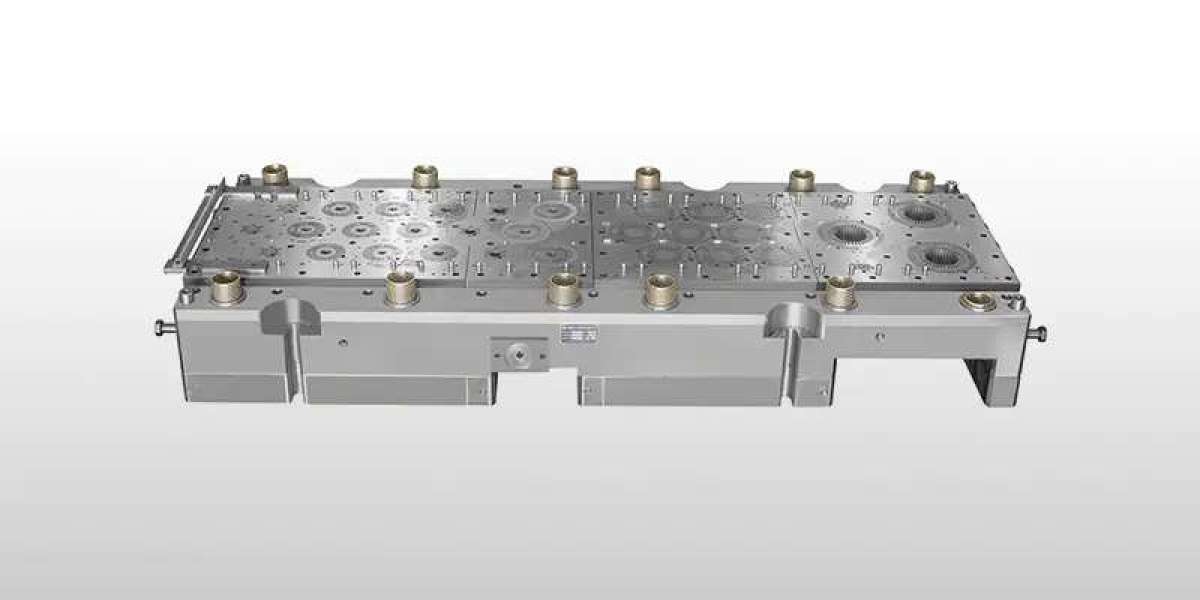

Specification Parameters

| Comprehensive life: | ≥160 million punches |

| Blade die life: | ≥5 million strokes/0.1mm |

| Mold structure: | Three-plate mold base + ball guide |

| Effective cutting edge height: | ≥8mm |

| Blade material: | DJ40 |

| Grooved die form: | Punch grooved die, slow wire finishing, the punch is polished using a special process to remove the oxidation layer |

| Guide parts: | Precision + high hardness |

| Blanking speed during running-in period: | 80-280 punches/minute |

| Blanking speed: | 280-300 punches/minute |

| Concentricity: | ≦0.05mm |

| Protection device: | Equipped with misfeed protection device |

| Punching burr: | ≦0.05mm |

| Riveting force: | 30N |

| Safety device: | Misfeed detection + equal height limit column |

| Product output form: | Conveyor belt Rotor control device Chute control device |

| Plate control device: | Cylinder |

| Mold base material: | Upper and lower mold seats P20, middle unloading seat P20, the second and fourth levels are made on the same set of molds and are interchangeable during production. The shaft hole can be used for three interchangeable pumping plates. |

| Spare parts provided: | 30% of wearing parts |

| Internal plate material: | Cr12MOV |

https://www.motorcoremold.com/product/