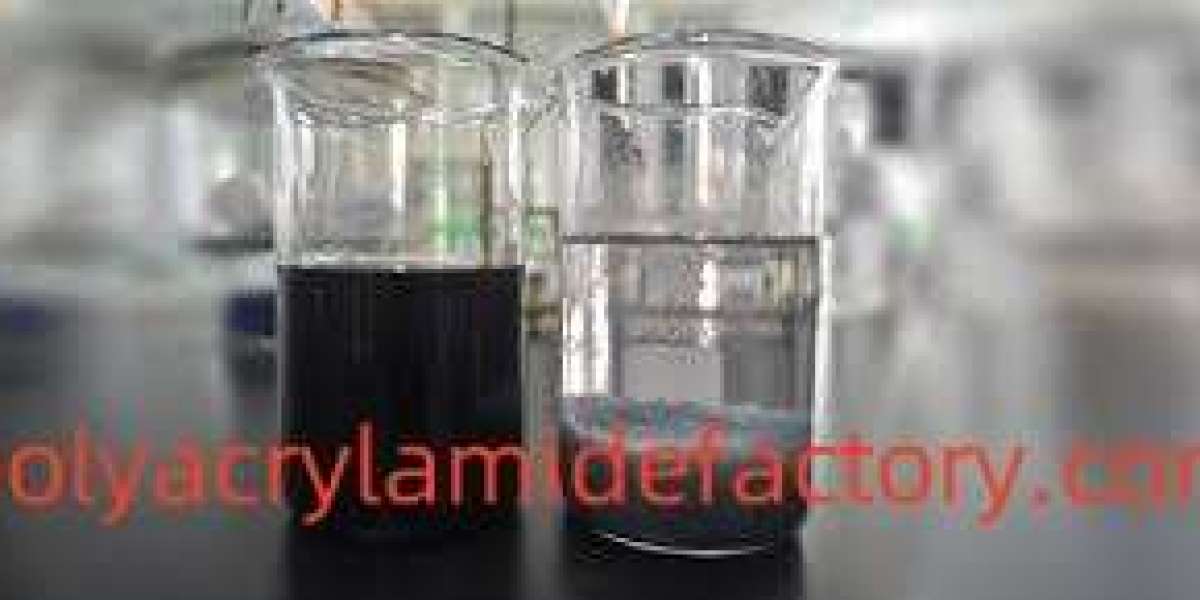

The use of Water treatment Polyacrylamide Chemicals has become common in a wide range of industrial wastewater applications. These materials support the removal of suspended solids and improve the separation of phases in treated water systems. Their performance relies not just on chemical composition but on the ability to adapt to different water characteristics across industries.

Industrial wastewater can include a variety of contaminants depending on the process that generates it. These may involve oil-based residues, organic particles, minerals or finely dispersed solids. Polyacrylamide chemicals are often selected due to their ability to aid in aggregation or binding of particles, making it easier to remove impurities through sedimentation or filtration.

What makes polyacrylamide effective in this field is not simply the base polymer but how the structure responds in real operational settings. The treatment goals may vary. In one setting, the focus may be on clarifying the water while in another, the emphasis might be on reducing total suspended solids. In either case, the chemical must remain active and stable throughout the treatment cycle.

In water systems with shifting compositions or fluctuating pH levels, performance consistency is essential. The use of polyacrylamide allows for treatment systems to maintain their routine functions without frequent adjustments. This helps minimize downtime and allows operators to focus on core tasks.

Additionally, polyacrylamide chemicals are used not only in end-of-pipe treatment but also as part of closed-loop systems where internal recycling of water is critical. In such applications, the chemical must avoid interfering with process-sensitive stages while maintaining its intended role in the water clarification process.

This level of adaptability makes polyacrylamide a valuable option in settings where water quality requirements shift or when regulatory expectations require stable outcomes. However, choosing the right formulation still requires an understanding of site-specific water properties and the desired treatment goals.

For those seeking to integrate such materials into their systems, it is worth exploring factories that specialize in tailored formulations for industrial water treatment. Polyacrylamidefactory supports this approach by offering products designed for use across various industrial wastewater applications. Their development focus is on stable function, operational simplicity and reliable performance in working conditions where input water quality varies over time.

To explore how polyacrylamide solutions can be part of your treatment strategy, consider learning more from Polyacrylamidefactory. Their focus on practical application and long-term use aims to support industries dealing with water clarity, material recovery and regulatory discharge needs.

Visit the following page for more insight into chemical use and application context https://www.polyacrylamidefactory.com/news/industry-news/fracturing-fluid-chemical-integrated-emulsion-for-reducing-resistance-and-carrying-sand.html